Sim-racing has gained in popularity in recent years, not least with the advent of high-performance and relatively affordable products. These days, you can literally walk into a supermarket, pick up a Logitech or Thrustmaster bundle, set it on a table or desk and go sim-racing.

Admittedly, the immersion experience will be diluted, but for the average gamer looking only to enjoy Forza Horizon 5 and its magnificent Mexican landscapes, it’s more than enough. For those who want to reproduce the sensations of a racing car in their living room, well, it’s a different story.

First of all, the equipment. You’ll switch from a belt- or gear-driven chainstay to a Direct Drive chainstay. Pedalboards will swap from spring-loaded to Load Cell. And that goes for virtually all other sim-racing peripherals and accessories, not forgetting the cockpit.

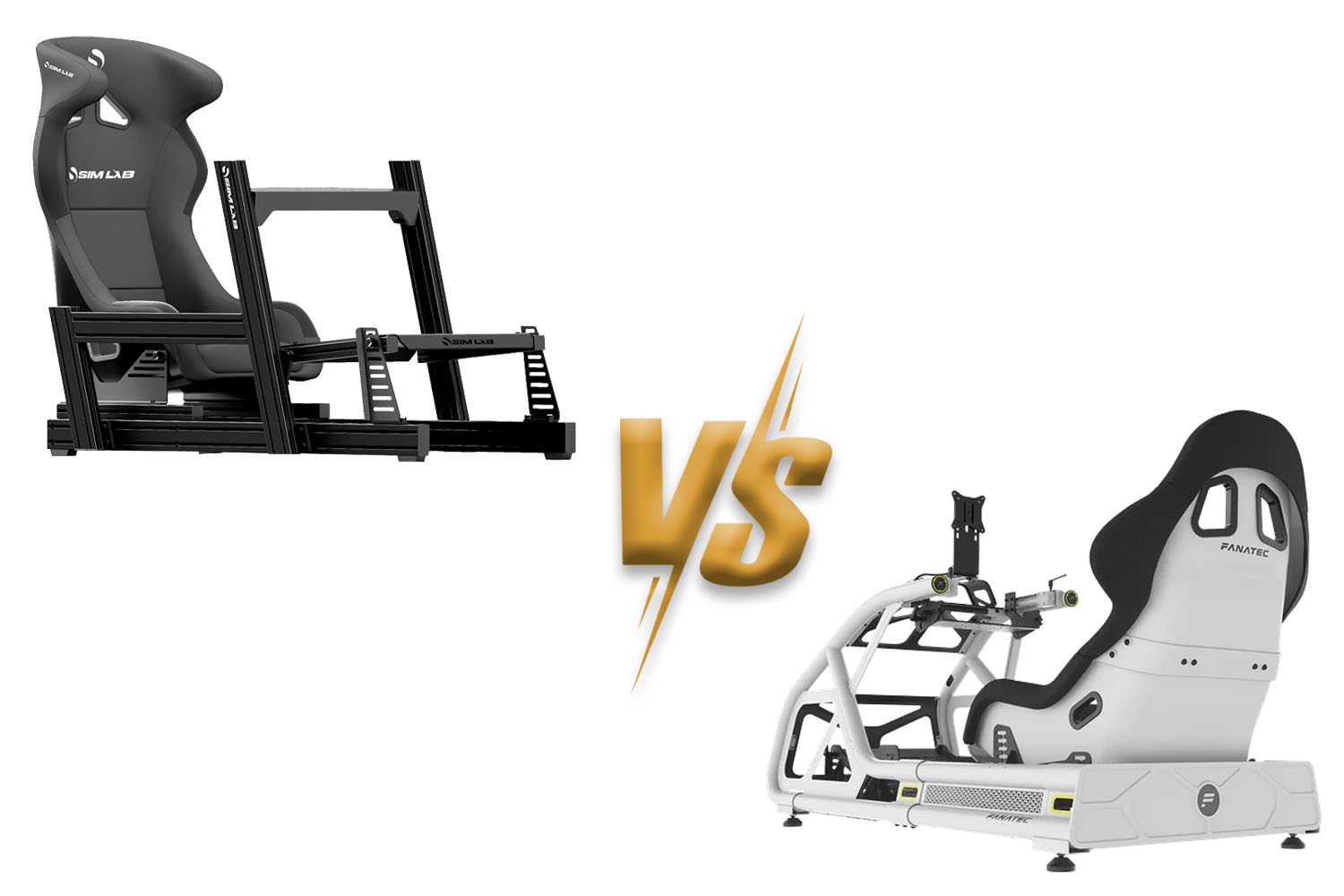

Ah, the famous cockpit, or rig to its friends. It’s a key element in sim-racing, especially for racing immersion. It serves as the structure housing all the racing equipment, offering realism, immersion and stability. However, there are several types of chassis on the market: stands, folding cockpits, tubular and aluminum profile chassis. Each has its advantages and disadvantages, and in what follows, we’re going to focus on two challengers: aluminium section and tubular.

Tubular frames – where simplicity meets budget

Let’s start with tubular cockpits. As their name suggests, they are made of steel tubes of varying diameters, depending on model and brand. Typically, the most popular models have a tube diameter of 50 mm, offering a good compromise between strength, lightness and affordability.

These chassis are easier to assemble, as the structure is identical for the model in question. Think of a tubular chassis as ready-to-wear: it’s more or less standard across the range, with a few extra accessories here and there.

On a tubular cockpit, you’ll find supports for cranksets, chainstays, sliding seats, monitors, shifters, dashboards and more. It all depends on the make and model in question.

The advantages of tubular

First of all, the price. Tubular frames are generally less expensive than their aluminum profile counterparts, although some models happily exceed €1,000 when properly optioned. But generally speaking, tubular frames are less expensive because of their simplicity of design and structure.

Then there’s the ease of assembly. Typically, and this applies to 95% of cases, tubulars are delivered with… tubes, which you’ll have to assemble with the help of an easy-to-read installation guide. This is both an advantage and a disadvantage, as all tubulars are more or less the same in terms of structure.

And finally, the styling. Chassis like some of PlaySeat are truly magnificent, especially those designed for Formula 1. Between design, color, seating and, above all, the feeling of being in a cage, tubular will always hold a place in my heart.

Disadvantages of tubular

In this world, nothing is perfect, and tubulars are no exception to the rule. First, rigidity. Sure, tubular cockpits are stiff, especially the top-of-the-range models, but you’ll still get some play. It’s inherent in the design, and there’s nothing you can do about it.

Then there are the limits for sim-racing peripherals, whether Direct Drive bases or cranksets. You’ll always have maximum values for these two pieces of racing equipment, even if it’s true that premium tubular models can accommodate a Fanatec Podium DD2 and its 25 nm of torque.

Finally, the most important element: customization. Most of the time, you’ll be limited by the accessories supplied by the tubular frame manufacturer. If the latter doesn’t offer a shifter mount, for example, you won’t be able to do anything about it.

Aluminum section frames – the key to rigidity and customization

We now move on to the aluminum profile frames. These are based on a structure of aluminum bars of various lengths and widths, with rails on all 4 sides of the tube. These rails are used to accommodate accessories or brackets for customizing the chassis.

Aluminum profile cockpits are very popular in sim-racing, especially for high-end configurations. They offer a very high level of accessory customization, with brackets mounted literally anywhere you like. But this comes at a price, much higher than their tubular counterparts.

The advantages of aluminum profiles

Obviously, it’s all about customization. You can have a chassis specific to your needs, and not necessarily with accessories and brackets from the same brand. Since aluminum tubes are standard, at least in terms of shape, you can get the basic structure from one brand, and accessories such as additional brackets from another. There are virtually no limits to your imagination, except perhaps your banker who will stop everything when you’re in the red.

Another advantage is rigidity. The aluminum cockpits are extremely solid, and can accommodate the most powerful sim-racing peripherals on the market. We’re talking about DD bases developing over 25 nm of torque, Load Cell cranksets with enormous braking pressure, and hydraulic ones too. This is impossible on a tubular chassis of any range. But to achieve this very high level of rigidity, you’ll have to shop at the top end of the chassis range.

Disadvantages of aluminum profiles

First of all, weight. Aluminium profile chassis are heavy because of the various parts that make up the structure, and above all because of their customization. You could say that every chassis is unique, as long as the driver has his or her own preferences.

Secondly, the complexity of assembly, which is a direct result of the weight. Not only will it take time (in hours) to assemble an aluminium profile chassis, as the parts are so numerous and heavy, but an extra pair of hands is highly recommended.

And thirdly, the price. An aluminum profile cockpit often starts at almost €1,000, and that’s without accessories and other supports. For this price, you’ll only get the bare-bone chassis, and you’ll have to add several hundred euros for the essential cockpit accessories.

I’d like to digress for a moment on the subject of stability. Aluminum profiles typically come in 3 bar widths: 80, 120 and 160. The larger the bar, the more stable it is. You’ll have a little play with 80 bars, less with 120 and none at all with 160.

And now, which one to choose?

There are two main reasons for choosing a chassis: price and the degree of immersion required. But there are other elements you need to consider, including:

- Design. Tubulars look a hell of a lot better than aluminum profiles, because they remind us of the roll cage on racing cars. And that alone, especially if the paintwork matches that of a particular team, can tip the balance.

- Customization. On this point, the profile wins loud and clear. But the latest tubular chassis have come a long way, offering a wide range of accessories. Admittedly, this will all be First Party, so it’s up to the manufacturer to decide, but they have to adapt to a constantly evolving market.

- Ease of assembly. There’s no contest here: tubular is much easier to assemble than aluminum profile, especially if you live alone or don’t have access to help.

- Availability. Since tubular chassis are very easy to assemble and consist of fewer parts, logistics are less of a problem with them, so they’ll be more available than others.

- Sturdiness. If you’re looking for the ultimate in sim-racing peripherals, i.e. the most powerful chainstays and hydraulic cranksets, then you’ll have to go the profiled route, as tubulars will quickly show their limits in terms of stability.

0 Comments